A Conformal Coating Stripper Removes Conformal Coatings From Electronic Components Using A Chemical Solution

|

| Conformal Coating Stripper |

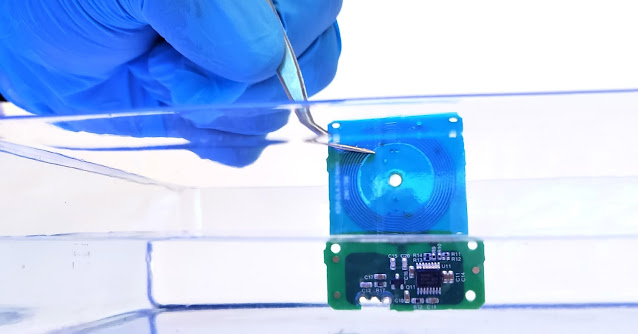

Conformal Coating is a protective coating that is often applied to electronic components

to protect them from environmental factors such as moisture, dust, chemicals,

and temperature changes. However, when it is time to repair or replace these

components, the conformal coating needs to be removed. This is where a

conformal coating stripper comes in.

A Conformal Coating Stripper is a chemical solution that is specifically designed to remove conformal coatings from electronic components. These strippers are formulated to dissolve the coating without damaging the underlying substrate or components. They are available in a variety of formulations, including liquid, gel, and aerosol.

The primary ingredients in conformal coating strippers are typically solvents, such as N-methylpyrrolidone (NMP), dimethyl sulfoxide (DMSO), and/or other organic solvents. These solvents dissolve the coating, making it easier to remove. Other additives may also be included to enhance the performance of the stripper, such as surfactants, pH adjusters, and corrosion inhibitors.

When selecting a Conformal Coating Stripper, it is important to consider the type of coating that needs to be removed. There are various types of conformal coatings, including acrylic, silicone, epoxy, and urethane. Each type of coating requires a different type of stripper. For example, an acrylic coating may be removed with a stripper that contains NMP, while a silicone coating may require a more aggressive stripper that contains dichloromethane.

The application method of the conformal coating stripper will also depend on the type of coating and the specific requirements of the application. Some strippers may be applied by brushing, dipping, or spraying, while others may require a more specialized application method. The user should always follow the manufacturer's instructions when applying a conformal coating stripper.

Water, salt, dampness, and stray currents are only a few of the elements that the rails and rail components are subjected to. These variables increase the risk of rail breaking by causing corrosion damage to rails, which can weaken the foot of the rails. Rails are effectively protected against corrosion by Railway Coatings. The coatings can be applied to all styles of flat bottom rails and are waterproof and insulated by nature.

Once the conformal coating has been dissolved by the stripper, it can be removed using a variety of methods, such as wiping, brushing, or rinsing with water. It is important to ensure that all of the coating has been removed before proceeding with any further repairs or replacements.

Comments

Post a Comment