The Emission Monitoring System consists of several components to be able to determine Gas

|

| Emission Monitoring System |

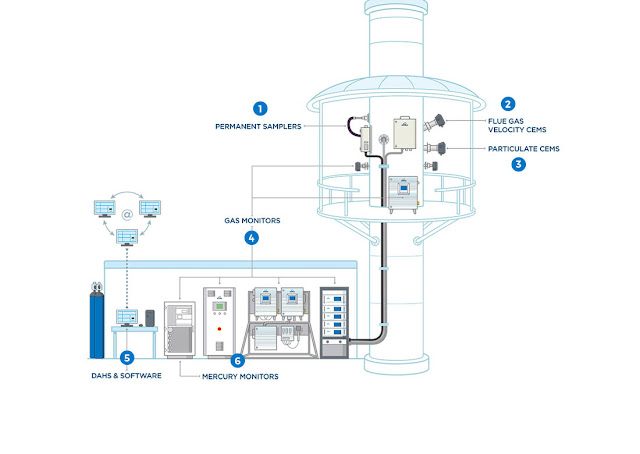

An Emission Monitoring System is

a tool used in industrial facilities to monitor flue gas for carbon monoxide,

oxygen, and carbon diode to offer information for combustion control. It is

made up of numerous components that can determine the concentration of gas or

particulate matter or the rate of emission of certain pollutants. EMS software

can generate results in units based on the appropriate emission limitations or

standards. EMS is often utilised in a variety of sectors, including power

generation, petrochemicals, chemicals, and oil and gas.

The growing reliance on

coal-fired power plants to generate energy is likely to grow the expansion of

the Emission Monitoring System. Many countries continue to rely heavily on

coal-fired power plants to generate electricity. Coal combustion emits a wide

range of airborne pollutants, including sulphur dioxide, mercury, lead,

nitrogen oxides, particulates, and other heavy metals. Long-term exposure to

these contaminants causes health problems such as breathing difficulties, brain

damage, asthma, heart problems, cancer, and early death.

Because it determines the

concentration of harmful gases or particulate matter discharged from the plant

and other industrial processes, the Emission

Monitoring System is critical in minimising carbon emissions. As

a result, emissions are restricted to permissible levels. Furthermore, growing

economies such as India have implemented emission rules to reduce air pollution

from automobiles and light commercial vehicles. For example, the government of

India implemented Bharat Stage VI regulations in April 2020, which reduced the

emission of hazardous gases such as nitrous oxide and particulate matter. Such

requirements have boosted the demand for pollution monitoring systems.

Emerging economies like China and

India are major users of coal-fired power generation. As a result, leading

players in the Emission Monitoring System market will benefit from attractive

chances. There are several restrictions in place to regulate air pollution, and

they are growing more rigorous by the year. Market participants can gain a

major edge by offering unique items at competitive costs.

The oil and gas sector emits a

large number of hazardous gases such as methane, sulphur dioxide, and others.

The Emission Monitoring System may collect data on emissions so that the

government can control the discharge of dangerous gases. To acquire a

competitive advantage, key organisations may focus on these prospects and

develop distinctive goods.

In the near future, hardware Emission

Monitoring Systems are projected to be in high demand. They are used to gather

emissions data in both CEMS and PEMS. PEMS is a software-based system that

predicts gas emissions using hardware components such as sensors, whereas CEMS

operates using hardware components. Because most facilities have installed

continuous Emission Monitoring Systems, the hardware system is projected to be

in high demand in the near future.

Comments

Post a Comment